Worldwide Flight Services (WFS) has been awarded IATA CEIV Pharma certification for its new €10 million Pharma Centre at Paris Charles de Gaulle Airport, for the handling of temperature-controlled healthcare and life science products.

Opened in September last year, the Centre is the only dedicated facility at the airport – the second largest air cargo gateway in Europe – with a team of dedicated and trained experts, temperature-controlled warehousing, and a transport fleet specifically adapted to guarantee pharmaceutical shipments integrity. Nearly 30 airlines and freight forwarders are already using the Pharma Centre, which is forecast to handle over 8,000 tonnes of products in 2020.

Hugo Rodrigues, Vice President Cargo France at WFS, said: “Investing in the Pharma Centre supports WFS’ strategy to broaden our product offering by supporting the needs of both our airline and forwarding customers as well as their customers, which, in this case, are major pharmaceutical companies that demand the highest standards of compliance to protect the integrity of their products. Gaining IATA CEIV Pharma certification so soon after opening the Centre recognizes our intention to meet the highest industry standards. It also adds to Paris CDG’s reputation as one of the world’s leading air cargo gateways.”

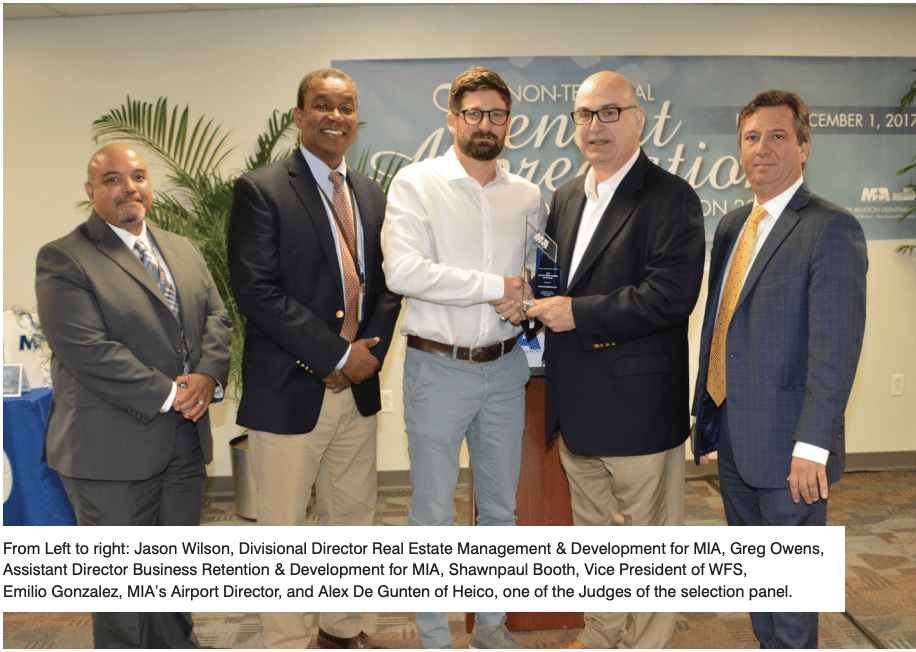

WFS has been investing in pharma handling centres at locations around its global network. In 2019, this included the opening of other facilities in Copenhagen, Johannesburg, Miami and new York JFK.

Located in the heart of the airport’s cargo area, WFS’ 2,400m² Pharma Centre in Paris offers landside and airside acceptance capabilities and significant temperature-controlled storage. The dedicated operation has its own docks and maneuvering area for the loading and unloading of temperature-controlled pharmaceutical shipments and incorporates:

-a dedicated room for loose cargo storage at +15 to +25°C with a capacity for 108 euro-pallets on four levels of racking.

-a separate cold room for loose cargo storage at +2 to +8°C with the capacity to store 47 euro-pallets on the ground, and with additional racking also available.

-a small freezing room for loose cargo storage at -20°C capable of handling 9 euro-pallets at a time.

-two temperature-controlled areas for +2 to +25°C for cargo unit load devices with a combined capacity to store 53 P2P or 106 AKE pallets.

New technologies used in the facility include digital systems to improve operational efficiency and shipment visibility. The warehouse management system (WMS) supports the use of barcode scanning for real-time storage capacity monitoring and management, ensuring constant tracking of shipments from the Pharma Centre to and from aircraft, with time and date statements available on demand. A temperature monitoring solution with a Cloud platform also collects temperature and humidity data in real-time via sensors and enables this information to be accessed on mobile devices.

Pulse, WFS’ cloud-based global platform for incident and inspection management has also been successfully deployed. With its mobile application functionality, Pulse enables real-time reporting of non-conformities and access to live dashboards. New functionalities are being developed to generate immediate automated reports for customers.

The WFS Pharma Centre is served by a fleet of exclusively-designed temperature-controlled three-pallet trailers and cool dollies as part of WFS’ end-to-end airport handling solution and works in accordance with the strict temperature requirements for specific pharmaceutical product groups. It is also equipped with controlled-access and screening, CCTV and alarm systems to ensure 24/7 safety and security, monitored by the company’s Security Operational Centre.